Montageschiene MS 41/41/41 - Test2

Group: 1711

Part number 100000

Versatile mounting rail for technical building equipment and industrial plant engineering – ideal for crossbars, wall brackets and support frames.

Maximum flexibility during assembly thanks to internal teeth and compatibility with siConnect system components such as slide element 41, TCS 1, hook head screw HZ and all CC components.

Available in various designs, e.g. as a trapezoidal rail for higher load requirements – perfect for customised mounting solutions.

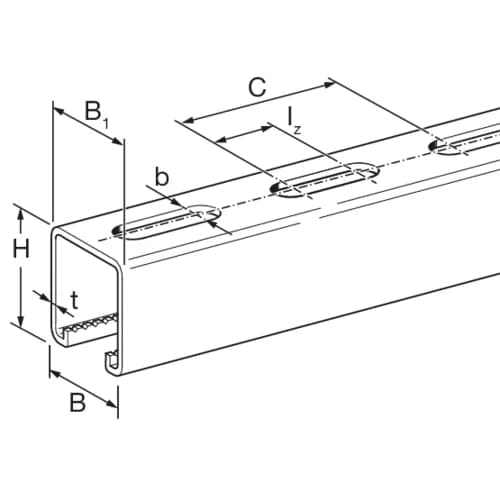

Technical Data

D1 | 5 mm |

D2 | 5 mm |

D | 3 mm |

B1 | 22 mm |

B2 | 66 mm |

BG1 | 54 mm |

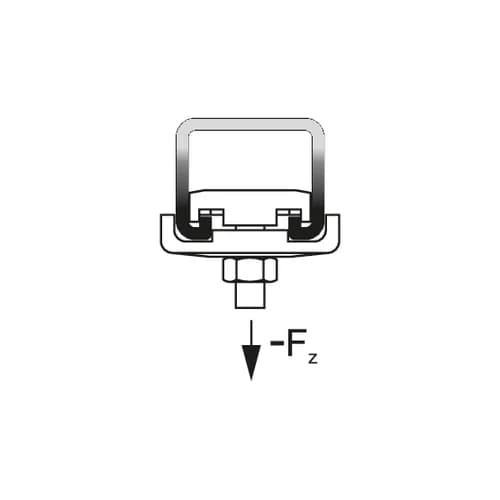

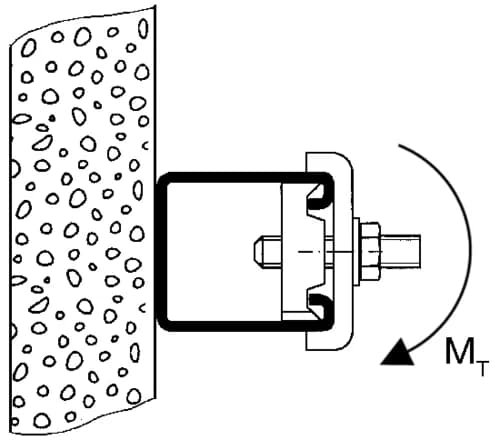

Load range

-VZ,perm. | 11,00 kN |

VZ,perm. | 12,00 kN |

-MX,perm. | 25 kNm |

MX,perm. | 23 kNm |

-MY,perm. | 22 kNm |

MY,perm. | 1,50 kNm |

-MZ,perm. | 11 kNm |

MZ,perm. | 11 kNm |

Resistance torque Wy | 0,25 cm³ |

Resistance torque Wz | 0,25 cm³ |

Moment of inertia Iy | 0,20 cm^4 |

Moment of inertia Iz | 46,00 cm^4 |

Radius of inertia iy | 0,54 cm |

Radius of inertia iz | 1,13 cm |

Moment of inertia It | 11,00 cm^4 |

Cross-section A | 0,67 cm² |

Technical specifications

Permissible long-term temperature | 130 °C |

Permissible short-term temperature | 17 °C |

Max. temperature | 12 °C |

Min. temperature | 11 °C |

max. temperature insulation | 9 °C |

min. temperature insulation | 2.000 °C |

max. temperature sliding element | 1 °C |

min. temperature sliding element | 97,3 °C |

Resistant to: | aliphatic chlorinated hydrocarbons, aliphatic and aromatic hydrocarbons, alkaline solutions, animal or vegetable fats, aqueous solutions up to 70 |

Conditionally resistant to: | ageing, alkaline solutions, aqueous solutions up to 70, aromatic solvents |

Not resistant to: | aliphatic chlorinated hydrocarbons, animal or vegetable fats, aqueous solutions up to 70, chlorine gas, diluted acids |

Thermal Conductivity λ {0°C} | λ 0,045 W/Mk |

Thermal Conductivity λ {10°C} | λ = 0,042 W/Mk |

Thermal Conductivity λ {20°C} | λ = 0,043 W/Mk |

Thermal Conductivity λ {30°C} | λ = 0,044 W/Mk |

Thermal Conductivity λ {40°C} | λ = 0,045 W/Mk |

Fire Performance | EL according to DIN EN 13501-1 |

Compressive strength | 70,00 N/mm² |

Permissible Tension σ{zul} | 188,00 N/mm² |

Permissible yield strength fy,perm. | 290,00 N/mm² |

Tensile Resistance | 3.700,00 N/mm² |

Sliding Friction μ | 0,5 |

Static Friction μ0 | 0,9 |

Static friction coefficient µ0 MPH/Profile | 0,9 |

Friction coefficient µ static Pipe shoe foot (without sliding plate) / siFramo and siMotec | 0,9 |

Friction coefficient µ static Pipe shoe foot (with sliding plate) / siFramo and siMotec | 0,9 |

Tear Resistance | 12,00 N/mm |

Elongation at break | 500 % |

Surface Resistance | 1 x 1011 Ohm |

Insertion Isolation | 12 dB(A) |

Spring deflection min. | 12 mm |

Spring deflection max. | 14 mm |

Elongation at break | 35 % |

Compression set | 13% (150° C/24 h) |

Contact resistance | 3 x 1015 Ohm |

Dynamic E-Module | 22,00 N/mm² |

Static E-Module | 22,00 N/mm² |

Hardness | 55+/-5° Shore |

Bulk Density | 12,00 g/cm³ |

Revound Elasticity | 30 % |

Water vapour diffusion resistance factor | 70000 |

Storage Temperature | ≥ 10°C |

Material base body | steelSteel Grade 4.6 |

Material insulation body | A4-50, ALU, A4-80, Stainless Steel VA |

Material sliding element | A4-80 |

Material connecting element | A4-70, Stainless Steel A2, Hybrid injection mortar, styrene-free, Metal |

Surface | pre-galavanised, uncoated |

Corossion class | C2, C5 |

Certification

CAD

Installation

If required, channels can be joined on site using:

Slot pattern II: Hexagon socket bolt M8 x 16, with a max. spacing of 250 mm between connecting points one point at each end.

Slot pattern III and IV: Clamping Unit KL (for details see product.

All Channels MS 41 are serrated on the inner edges and thus can be combined with many other Sikla products, e.g. Channel Nut, End Support WBD, Beam Clamp TCS 1. Particularly effective combinations are possible using other Pressix components. All types can be used as guide and support channels by inserting Slide Block 41 inside the channel.